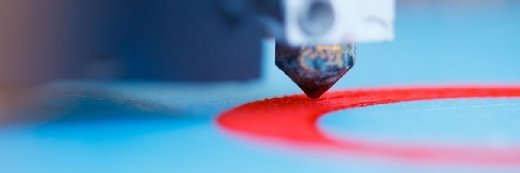

nikkytok - Fotolia

INDO-MIM taps 3D printing in precision manufacturing

The precision metal parts manufacturer is using HP’s Metal Jet S100 printers to produce components using metal powder for the automotive, healthcare and other industries

India’s INDO-MIM is leveraging 3D printing to produce high-precision metal parts for the automotive, space, defence and other industries, underscoring advances in additive manufacturing that promise to reduce production time and cost.

During a visit to an INDO-MIM facility in Doddaballapur, located about 40km from Bengaluru, company executives showed how the use of HP’s Metal Jet S100 printers can be used to print metal parts with metal powder.

“As a powder-based company, we can develop systems that give us the ability to unlock expertise, design capabilities and adjust geometries, adding value to material selection, properties and systems,” said Krishna Chivukula Jr, CEO of INDO-MIM.

Savi Baveja, president of personalisation and 3D printing at HP, noted that additive manufacturing, as a disruptive technology, is expected to be more widely adopted and can be used for fluidics parts with support for complex geometries. “It can also produce lattice structures for the automotive industry,” he added.

INDO-MIM is among the world’s largest metal injection molding companies, with production plants in India, the US and the UK. Its customers are spread across North America, Europe, Southeast Asia, the Middle East and Africa.

With its HP Metal Jet S100 printers, the company plans to supply machine parts to the Defence Research Development Organisation (DRDO) and Indian Space Research Organisation (ISRO). DRDO is responsible for developing technology for use by the military, while ISRO is the primary space agency of the Indian government.

Large-scale production

INDO-MIM is the first company in India to support large-scale production of 3D-printed high-precision metal parts. Producing 3D-printed complex machine parts does not require prototyping, which lowers cost and speeds up production from days to hours.

The applications of 3D printing are diverse, ranging from aerospace and defence to automobile and consumer electronics. In the automotive industry, for example, 3D-printed parts like engine blocks and chassis structures can be made lightweight and durable, offering superior strength-to-weight ratios, thereby enhancing vehicle performance and fuel efficiency.

In healthcare, the technology can help to produce patient-specific medical devices and implants. The use of 3D-printed cutting guides, for example, can help orthopaedic surgeons to ensure precise surgical outcomes.

Sustainability is a key focus of INDO-MIM’s 3D printing facility. Thanks to predictable powder usage, very little powder is left over after a production run, with any remaining power repurposed where possible. About 90-95% of the facility’s power comes from renewable sources.

Today, INDO-MIN works with materials like tool steel and stainless steel, but as customer demands increase, it could work with other materials such as alloys and titanium, said Chivukula. Meanwhile, the company is working on a process application to reduce powder shrinkage during additive manufacturing, which can be as high as 19%.

Through its partnership with HP, INDO-MIM is also testing new materials such as HP’s M2 tool steel. These new materials are expected to improve material properties and precision, making metal 3D printing even better.

INDO-MIM has invested in three HP Metal Jet S100 printers. One of them will focus on new material development, while the other will drive application development and cater to customers in India, the Middle East and the rest of Asia-Pacific. The third printer has been installed at the INDO-MIM facility in Texas, US.

Read more about IT in India

- Manipal Hospitals’ video consultation services and a nurse rostering app are among the tech innovations it is spurring to improve patient care and ward operations.

- VMware customers in India and the Asia-Pacific region are concerned about higher costs even as they see the benefits of subscription-based pricing and product bundling in the longer term.

- Political parties in this year’s high-stakes elections are leveraging AI for the first time, but measures to curtail misuse must continue to evolve with the rapid developments of the technology.

- India is looking to shore up its supercomputing capabilities, but more needs to be done to realise its ambition of becoming a world leader in the field.